Mould Specifications

|

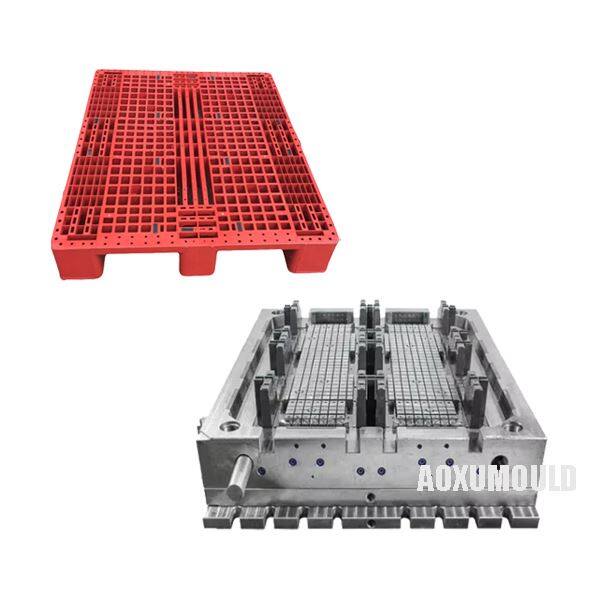

Mould name |

PP Pallet Mould |

|

Product material |

HDPE, plastic |

|

Product Size |

1300X1100X150mm |

| Product weight |

21 kgs |

|

Mould material for cavity &. Core |

P20 |

|

Mould base |

C45 |

|

Injection system |

Hot runner |

|

Suitable injection machine |

3000T |

|

Mould size |

1960X1750X850mm |

|

Mould lifetime |

more than 300,000pcs |

Advantages Of PP Pallets

1. High Durability & Strength

PP pallets are resistant to impact, cracking, and breaking, making them ideal for heavy-duty logistics and warehousing.

They can withstand harsh environments, including extreme temperatures and moisture.

2. Lightweight Yet Sturdy

PP pallets are much lighter than wood or metal pallets, reducing transportation costs while maintaining load-bearing capacity.

3. Hygienic & Easy to Clean

Non-porous surface prevents bacterial growth, making them suitable for food, pharmaceutical, and chemical industries.

Can be easily washed or sterilized without degradation.

4. Corrosion & Chemical Resistance

PP is resistant to acids, alkalis, and other chemicals, ensuring long-term usability in industrial applications.

5. Cost-Effective in Long Run

Longer lifespan than wooden pallets (which can rot or splinter).

Lower maintenance costs (no need for repairs like nails or repainting).

6. Customizable Design

Injection molding allows for complex shapes, reinforced structures, and branding options (logos, textures, colors).

Can be designed with anti-slip surfaces, RFID tags, or nesting features for space-saving storage.

7. Environmental Benefits

100% recyclable, reducing waste compared to single-use wooden pallets.

Can be made from recycled PP material, supporting sustainability goals.

8. Consistency & Precision

Injection molding ensures uniform quality, tight tolerances, and repeatability in mass production.

9. Reduced Fire Hazard

PP is inherently flame-retardant (unlike wood), meeting safety standards in warehouses.

10. Global Compliance

Meets international standards (e.g., ISO, FDA, EU regulations) for export and logistics.

Common Types of PP Pallets

1. Standard Nestable PP Pallets

>Lightweight (30-50% lighter than wood)

>Space-saving (stackable/nestable when empty)

>Ribbed design for strength without excess weight

>Applications:

Export packaging

Retail distribution

Light-to-medium load storage

2. Heavy-Duty Rackable PP Pallets

>Reinforced structure (high load capacity: 1,500–3,000 kg)

>9-leg or block design for forklift/racking compatibility

>Anti-slip surface options

>Applications:

Warehouse racking systems

Automotive parts handling

Bulk industrial goods

3. Hygienic Closed-Deck PP Pallets

>Smooth, non-porous surface (easy to clean, FDA-compliant)

>No cracks or gaps (prevents bacterial growth)

>Often white or light-colored for cleanliness visibility

>Applications:

Food & beverage industry

Pharmaceutical logistics

Chemical storage

4. Anti-Slip/Textured Surface PP Pallets

>Diamond or grid patterns on deck for grip

>Rubberized coatings (optional)

>High friction to prevent load shifting

>Applications:

Cold storage (wet environments)

Glass/metal part transport

Automated conveyor systems

Design For Product &. Mould

Key Components of A PP Pallet Injection Mould

1.Mould Cavity & Core

The cavity shapes the outer surface of the pallet, while the core forms the inner structure (e.g., ribs, reinforcements).

Designed for high-pressure injection of molten PP.

2.Runner &. Gate System

Channels that deliver molten plastic into the mould cavity.

Hot runner systems (preferred for PP pallets) reduce waste and improve efficiency.

3.Ejection System

Pins or plates that push the finished pallet out after cooling.

4.Cooling Channels

Circulate water or oil to cool the mould quickly, reducing cycle time.

5.Venting System

Prevents air traps and ensures smooth filling of the mould.

5.Clamping Unit

Holds the mould tightly shut during injection (high clamping force required for large pallets).

Package &. Delivery

Mould Components

Mould Steel

Hot Runner System

Standard Parts

How We Control PP Pallet Mould Quality?

|

FAQ

|

>1. What is PP Pallet Injection Moulding? PP (Polypropylene) pallet injection moulding is a manufacturing process where molten plastic is injected into a precision mould under high pressure to produce durable, lightweight plastic pallets for logistics and material handling. >2. What Types of Pallets Can You Produce? We manufacture: Nestable Pallets (space-saving storage) Rackable Pallets (heavy-duty for warehouse use) Export Pallets (lightweight, ISPM 15 compliant) Anti-Slip Pallets (safety-enhanced surfaces) Closed-Deck Pallets (hygienic, no debris accumulation) >3. Can You Customize Pallet Designs? Yes! We offer: Custom sizes, shapes, and load capacities (e.g., 1200x800mm Euro pallets). Branding options (logos, colors, textures). Special features (reinforced legs, RFID tags, fire-retardant additives). >4. What's the Cost of a PP Pallet Mould? Mould costs vary by: Size & complexity (e.g., multi-cavity moulds cost more), Material (steel type), Custom features (hot runner systems, special textures). >5. What are the advantages of using PP pallets injection mould for manufacturing pallets? PP pallets injection mould offers high durability, excellent resistance to chemicals, and a smooth surface finish that is easy to clean. These pallets are also lightweight and stackable, making them ideal for transportation and storage. >6. How long does it take to manufacture PP pallets using injection moulding? The production time for PP pallets using injection moulding can vary depending on the complexity of the design and the size of the order. Typicaly it will take about 60-75 days for T1.

|

Customers' Feedback