Mould Specifications

|

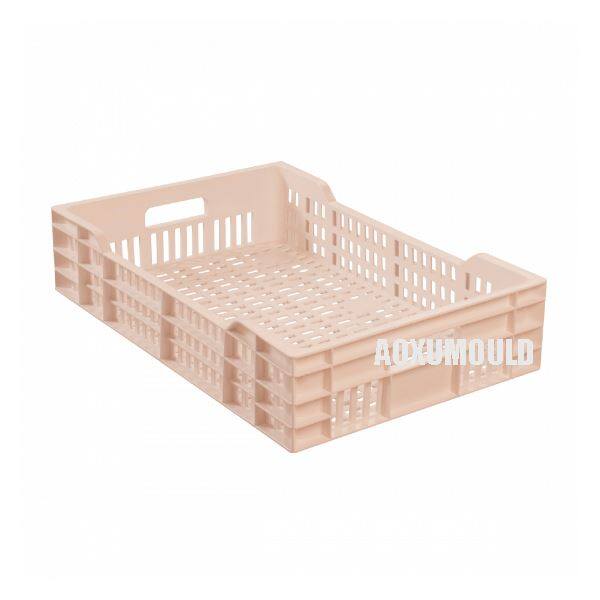

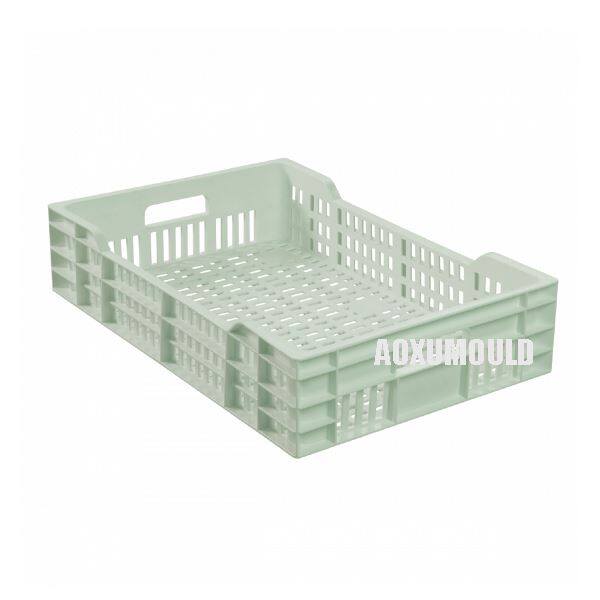

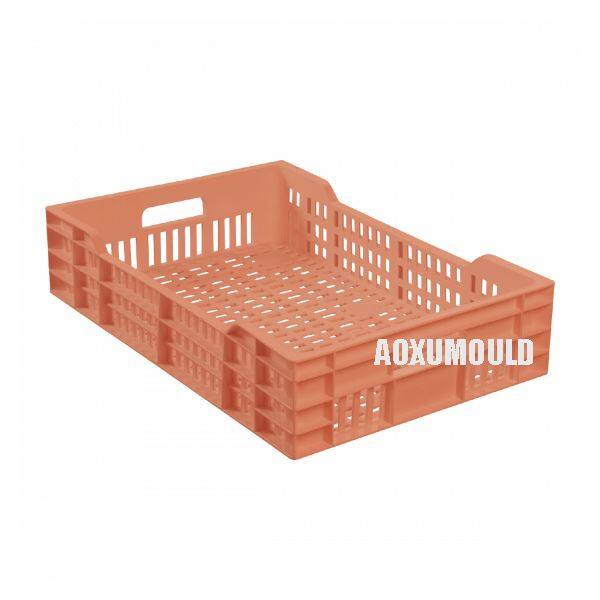

Mould name |

Ventilated Crate Mould |

|

Product material |

HDPE, plastic |

|

Product Size |

400X300X175mm |

| Product Weight | 0.8KG |

|

Mould material for cavity &. Core |

P20, 718, 2738 |

|

NOs of cavity |

1 cavity |

|

Injection system |

Cold/Hot runner |

|

Suitable injection machine |

650T |

|

Mould size |

780X680X565mm |

|

Mould lifetime |

more than 500,000pcs |

Advantages of Plastic Ventilated Crates

1. Improved Air Circulation & Freshness

Designed with holes, slots, or mesh patterns to allow airflow, preventing moisture buildup.

Ideal for perishable goods (fruits, vegetables, seafood) to extend shelf life.

2. Lightweight Yet Durable

Made from high-impact plastics (PP, HDPE) that are lighter than wood or metal but still strong.

Resistant to cracking, corrosion, and chemicals (unlike wood or metal).

3. Stackable & Space-Efficient

Designed with interlocking or nesting features for secure stacking.

Saves storage and transport space, reducing logistics costs.

4. Easy to Clean & Hygienic

Smooth plastic surfaces prevent dirt and bacteria buildup.

Can be washed, sanitized, or even steam-cleaned (unlike porous wood or weak cardboard).

5. Long Lifespan & Cost-Effective

Unlike cardboard (single-use) or wood (rots over time), plastic crates last for years.

Reusable & recyclable, reducing long-term costs.

6. Customizable Designs

Available in different sizes, colors, and vent patterns for specific needs.

Can include reinforced handles, RFID tags, or foldable designs.

7. Eco-Friendly Options

Made from recycled plastics (rHDPE, rPP).

Can be recycled again at the end of their lifespan.

8. Better Product Protection

Ventilation prevents condensation and mold growth.

Sturdy construction reduces crushing or damage during transport.

How Are Ventilated Crates Manufactured?

Mould Design – CAD/CAM software creates precise mould cavities.

Steel Mould Fabrication – Hardened steel (P20, H13) for durability.

Injection Molding – Molten plastic injected into the mould under high pressure.

Cooling & Ejection – Crates solidify and are ejected via pins/stripper plates.

Post-Processing – Trimming, quality checks, and packaging.

Designs For Product &. Mould

What Are The Key Design Features Of Ventilated Crates?

1. Ventilation Patterns

Holes/Slots: Circular, square, or elongated slots for airflow.

Mesh Designs: Fine or coarse grids for maximum breathability.

Strategic Placement: Vents on sidewalls, base, and lid to prevent condensation.

Purpose: Prevents mold, spoilage, and moisture buildup in perishable goods (fruits, vegetables, seafood).

2. Structural Reinforcement

Ribs & Thickened Edges: Adds strength without extra weight.

Corner Supports: Reinforced corners for stacking stability.

Base Design: Flat, anti-slip, or raised patterns for drainage.

Purpose: Ensures durability under heavy loads and repeated use.

3. Stackability & Nestability

Interlocking Lids/Rims: Secures stacked crates during transport.

Tapered Walls: Allows nesting when empty (saves storage space).

Stacking Ledges: Prevents crushing of lower crates.

Purpose: Maximizes storage and transport efficiency.

4. Material & Surface Finish

Smooth Surfaces: Easy to clean, hygienic, and resistant to bacteria.

Textured Bases: Anti-slip properties for wet environments.

UV-Stabilized Plastics (for outdoor use): Prevents degradation from sunlight.

Purpose: Enhances longevity and sanitation.

5. Customizable Add-Ons

Branding: Embossed logos, QR codes, or color options.

RFID Tags: For tracking in supply chains.

Drainage Plugs: For liquid-containing goods.

Lids & Dividers: For secure or compartmentalized storage.

Purpose: Tailored solutions for specific industries.

Design Considerations for Hot Runner Crate Moulds

(A).Gate Location & Type

Edge Gates: Common for crates (minimal marks, easy trimming).

Valve Gates: Best for large crates (prevents drooling, precise control).

Submarine Gates: Used for hidden gate marks.

(B) Thermal Management

Balanced heating zones prevent uneven flow.

Insulation plates reduce heat loss to the mould.

(C) Venting for Ventilated Crates

Hot runners require proper venting to avoid gas traps (especially in crates with many holes).

Vent slots or porous steel inserts help release trapped air.

(D) Material Compatibility

Works best with PP, HDPE, and recycled plastics (common for crates).

Avoid materials prone to degradation (e.g., PVC).

>Choose Hot Runner If:

Producing high volumes (>50,000 crates/year).

Need cost savings on material waste.

Require faster cycles & better quality.

>Choose Cold Runner If:

Low-budget or prototyping.

Small production runs.

Mould Components

Mould Steel

Hot Runner System

Standard Parts

Package &. Delivery

FAQ

>1. What materials are used for ventilated crates?

Common plastics include:

Polypropylene (PP) – Lightweight, chemical-resistant, cost-effective.

High-Density Polyethylene (HDPE) – Stronger, impact-resistant, UV-stabilized for outdoor use.

Recycled Plastics (rPP/rHDPE) – Eco-friendly option.

>2. Can I customize the design of the ventilated crate injection moulds?

Yes, we offer customization options for our ventilated crate injection moulds to meet the specific needs and requirements of our customers. Our experienced team will work with you to create a design that best suits your needs.

>3. What industries use ventilated crates?

Agriculture (fruits, vegetables, flowers).

Fisheries & Meat (prevents moisture buildup).

Retail & Supermarkets (display & storage).

Logistics (stackable, reusable transport).

>4. How long does it take to manufacture ventilated crate injection moulds?

The manufacturing process for our ventilated crate injection moulds typically takes 45-55 days, depending on the complexity of the design and the quantity of moulds needed. We strive to deliver our products in a timely manner to ensure customer satisfaction.

>5. Are ventilated crates recyclable?

Yes! Most are made from PP or HDPE, which are widely recyclable. Some manufacturers use post-consumer recycled plastic for sustainability.

>6. Are your ventilated crates suitable for food storage and transportation?

Yes, our ventilated crate injection moulds are designed to meet food safety standards and are suitable for storing and transporting food products. They are also easy to clean and maintain, making them a convenient and hygienic option for food-related industries.

>7. How do I maintain a ventilated crate mould?

Regular cleaning (remove plastic residues).

Lubrication (ejector pins, slides).

Inspect for wear (cavity damage, corrosion).

Proper storage (dry, temperature-controlled).

Customers' Feedback