Mould Specifications

|

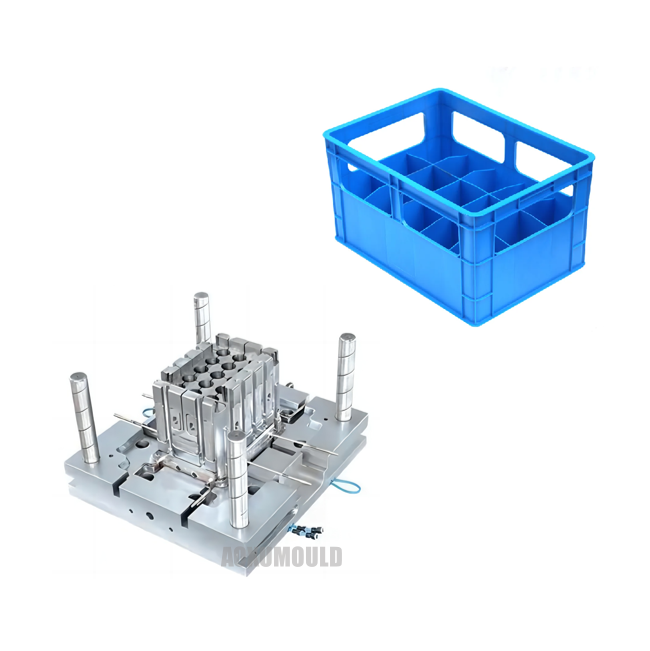

Mould name |

Plastic Bottle Case Mould |

|

Product material |

HDPE |

|

Product Size |

506X366X277mm |

| Product Weight | 2KG |

|

Mould material for cavity &. Core |

P20/718H/H13/2738 |

|

NOs of cavity |

1 cavity |

|

Injection system |

Hot runner 4 point gates |

|

Suitable injection machine |

550T |

|

Mould size |

850x710x530mm |

|

Mould lifetime |

more than 500,000pcs |

|

Delivery Time |

50 days |

Advantages And Disadvantages of Plastic Bottle Case Mould Hot Runner 4 Point Gates

The 4-point gates hot runner for plastic bottle case mould is a relatively common injection molding technology, which has many advantages, such as optimizing product quality, improving production efficiency, and reducing production costs. At the same time, it also has some drawbacks, such as the need for more high-temperature resistant materials and relatively high maintenance costs. Now let's specifically analyze the advantages and disadvantages of this technology.

Firstly, one of the advantages of the 4-point gates of the hot runner for plastic bottle case mould is that it can achieve production automation and improve production efficiency. Hot runner technology enables plastic materials to flow more smoothly during the injection molding process, thereby reducing filling time and enhancing production efficiency.

Secondly, the 4-point gates of the hot runner can optimize the product quality. Hot runner technology can effectively prevent product defects such as bubbles and short-circuiting, thereby enhancing the quality stability of the products.

In addition, hot runner technology can also reduce production costs. As hot runner technology can enhance production efficiency, reduce the rate of defective products, lower production costs and boost the competitiveness of enterprises.

However, there are also some drawbacks to the 4-point gates of the hot runner in the plastic bottle case mould. Firstly, hot runner technology requires more high-temperature resistant materials to withstand high-temperature environments, which will increase the manufacturing cost of moulds. Secondly, the maintenance cost of hot runner technology is relatively high, requiring regular cleaning and maintenance, which increases the operating costs of enterprises.

Design For Product &. Mould

What Methods Are To Improve Injection Molding Cycle Time of Plastic Bottle Case?

1. Optimize mould design: By optimizing the structure and process of plastic bottle case mould, the molding cycle time can be reduced. For instance, adding drainage channels to the mould can enhance the working efficiency of the injection molding machine and reduce the cooling time, etc.

2. Adjust the parameters of the injection molding machine: Reasonably adjusting parameters such as injection speed, pressure, and temperature can enhance molding efficiency and shorten the molding cycle. According to different plastic raw materials and product design requirements, adjust the corresponding parameters to achieve the best molding effect.

3. Adopt advanced injection molding equipment: Selecting injection molding machines with stable performance and convenient operation can significantly enhance production efficiency and shorten the molding cycle. Advanced injection molding equipment features higher precision and stability, which can ensure the stability of product quality.

4. Strengthen production management: Through reasonable production planning, production processes, personnel training and other management measures, production efficiency can be enhanced and the molding

cycle can be shortened. Establishing a sound production management system helps enhance production organization and execution capabilities, and reduces waste and downtime during the production process.

5. Continuously improve process technology: Injection molding technology is also constantly innovating. By introducing new technologies and new processes and improving the production process, production efficiency can be enhanced and the molding cycle can be shortened.

What Are The Quality Inspection Procedures For Plastic Bottle Case Mould?

Quality inspection of plastic bottle case mould is an important link to ensure product quality and production efficiency. Now let's take a look at the process of quality inspection for plastic bottle case mould.

Firstly, before the quality inspection of plastic bottle case mould, the inspection standards should be clearly defined. According to the design requirements and product specifications of plastic bottles case, determine the quality standards of the moulds. This can ensure the accuracy and reliability of the detection.

Secondly, conduct an appearance inspection. Check whether the surface of the plastic bottle case mould is smooth and whether there are any defects such as cracks or burrs. Visual inspection can preliminarily determine the quality condition of the mould.

Thirdly, conduct size inspection. Measure the dimensions of each part of the mould and check whether they meet the design requirements. Dimensional inspection is a key step in testing the accuracy of moulds and the level of craftsmanship.

Fourthly, material inspection is carried out. Test the quality and performance of the materials used in the mould to ensure that they meet the production requirements. Material inspection has a significant impact on the service life and product quality of plastic bottles and boxes.

Finally, conduct the actual production inspection of the mould. Put the moulds into the production line and test their production efficiency and stability. The quality and performance of the mould can be verified through actual production inspection to see if they meet the requirements.

The Importance of TO Test Mould For Plastic Bottle Case Mould

When the plastic bottle case mould is finished, conducting TO test moulds is a very important step. TO mould testing is the process of prototyping a mould. Through mould testing, the rationality and accuracy of the mould design can be verified, providing a guarantee for subsequent production.

1., TO mould testing can verify the accuracy of the mould design. When designing moulds, there may be some errors or omissions. Through TO mould testing, they can be discovered and corrected in a timely manner to ensure that the products made by the mouds meet the design requirements, improving production efficiency and product quality.

2., TO mould testing can test the stability and durability of the mould. Moulds are subjected TO significant pressure and wear during production. Through TO mould testing, the durability and stability of moulds can be verified, providing technical support for subsequent mass production.

3., TO mould testing can identify problems in advance and solve them promptly. During the mould trial process, some problems may arise, such as product deformation and poor molding. By promptly identifying and resolving these issues, similar situations in subsequent production can be avoided, saving time and costs.

4, The TO trial mould can provide references and optimization directions for production. Through TO mould testing, one can understand the process and technical requirements of mould making, providing a reference for subsequent production. Moreover, based on the results of the mould testing, the mould can be optimized and improved to enhance production efficiency and product quality. In the production process of plastic bottle case mould, TO test moulds is a very important step. TO mould testing is the process of prototyping a mould. Through mould testing, the rationality and accuracy of the mould design can be verified, providing a guarantee for subsequent production.

Mould Components

Mould Steel

Hot Runner System

Standard Parts

Package &. Delivery

FAQ

>1. What is plastic bottle case mould?

It is a tool used to produce plastic parts by injecting plastic into the mould cavity.

>2. What materials are used to make plastic bottle case mould?

The most common materials used to make injection moulds are high-quality steel, such as P20, 718, 2738, etc.

>3. What is the process of making a plastic bottle case mould?

The process of making a mould includes design engineering, machine programming, tooling fabrication, mould testing and validation.

>4. Can moulds be customized to specific product requirements?

Yes, moulds can be customized to specific product requirements depending on the design and specifications of the project.

>5. What are some factors to consider when making our plastic moulds?

Some factors to consider when making plastic moulds include product design, plastic material selection, mould material selection, injection moulding machine capacity, cooling time, and mould maintenance requirements.

>6. How long does it take to make one set of mould?

The time it takes to make mould can vary depending on the complexity and size of the mould.

However, it usually takes between 6 and 8 weeks.

>7. What can be done to ensure the mould quality?

To ensure mould quality, proper design and engineering, high-quality materials, and strict quality control procedures should be employed during the entire process of making the mould.

>8. How long can a mould last?

The lifespan of a mould can vary depending on the quality of the mould, maintenance practices, and operating conditions. A well-maintained mould can last for hundreds of thousands of cycles.

>9. What are the benefits of making plastic injection moulds?

Some benefits of making plastic moulds include faster production times, lower costs per unit, high accuracy, and the ability to produce complex shapes and designs.

>10. Can our plastic bottle case mould be repaired and maintained?

Yes, it can be repaired and maintained to extend their lifespan. Regular maintenance can prevent breakdowns and ensure consistent quality.

Customers' Feedback