Mould Specifications

|

Mould name |

Mobile garbage bin mould |

|

Product material |

High-density polyethylene (HDPE) |

|

Product Dimensions |

1020mm(W) x 1370mm(L) x 1325mm(H) |

|

Product capacity |

1100L |

|

Product Weight |

51kg |

|

Mould material for cavity &. Core |

P20 |

|

Mould base |

C45 |

|

Mould cavity |

1 cavity |

|

Injection system |

Hot runner feeding system |

|

Suitable injection machine |

4000T |

|

Mould size |

2385X1925X1250mm |

|

Mould Weight |

17500T |

|

Mould lifetime |

more than 300,000pcs |

|

T1 Time |

After design is finalized, 65 days |

Product Characteristics

1100L mobile garbage bin is a large garbage sorting container with many excellent features that can have a positive impact on our environment and life.

First of all, the 1100L garbage bin is made of high quality plastic materials, with light, strong, corrosion resistance and other excellent characteristics, can withstand conventional impact and pressure, strong durability.

Secondly, the 1100L plastic mobile garbage bin has a large capacity and multi-functional design, and can be installed in a variety of places, such as public places, hospitals, supermarkets, schools, etc., as well as indoor and outdoor. Not only can it be used to collect various types of garbage, such as kitchen waste, paper, bottles, plastics and metals, but also can be used to separate and classify garbage, making garbage disposal more convenient and environmentally friendly.

In addition to powerful performance and efficient design, the 1100L mobile garbage bin also has the advantage of being easy to operate and maintain. The garbage bin is equipped with a professional garbage bag holder, which makes it easy to change garbage bags and is also very convenient when cleaning and disinfecting.

Overall, the 1100L plastic bin is a quality product that is powerful, strong in structure, easy to use and maintain. It can not only help us improve waste disposal and environmental sanitation problems, but also promote our quality of life and health level. Let's actively use and promote this excellent garbage sorting container, and work together to create a better environment and future.

Customized Lids For 1100L Mobile Garbage Bin

1100L plastic garbage can is one of the important tools of urban waste classification, in order to better achieve the goal of garbage classification and recycling, the garbage can should be equipped with different types of LIDS. Here is an introduction to the two types of covers and their advantages.

The first, openable LIDS: These LIDS make it easier for people to place garbage and clean trash cans. When people put garbage into the trash can, the lid can automatically spring up, and after disposing of garbage, only need to gently press the lid to close. In addition, this kind of lid has a small hole at the top to help the trash can drain the accumulated gas. For urban waste classification management, this kind of lid makes it more convenient to put garbage, and also makes it easier to clean the trash can.

The second type, sliding lid: This lid can better avoid odor and prevent the breeding of pests, keep the garbage can clean and tidy. The lid uses a sliding design to cover the entire trash can, so that debris cannot be emitted. In addition, the lid design is also very lightweight and easy to use. This kind of lid is very suitable for storing organic waste and other odorous garbage, which can avoid odor diffusion and ensure a clean and sanitary environment.

In short, 1100L plastic trash can as a basic tool for urban waste classification, through the selection of different types of covers, can better achieve the goal of garbage classification and recycling. This can help people better put garbage, make recycling and loading garbage more convenient, but also effectively avoid the hygiene and odor problems in garbage cleaning. Let's help garbage classification and build a better city together!

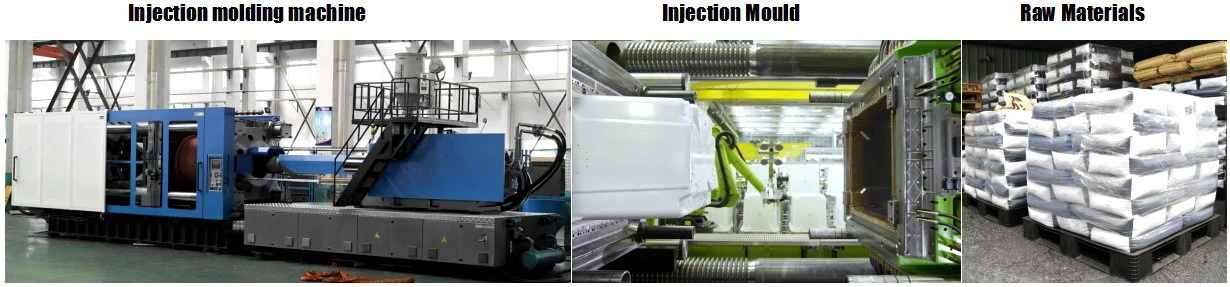

1100L Plastic Garbage Bin Production Line

1100L plastic garbage bin production line is a very important production line, it can help us produce a large number of high-quality plastic trash cans, which plays an important role in our living environment.

The production of 1100L mobile garbage bins requires a series of processes, from raw material storage to production and processing to production testing, each link requires fine operation and quality control. Therefore, our production line is equipped with the appropriate technology and equipment to ensure that we can efficiently produce plastic garbage bins that meet the requirements and can achieve sustainable production.

Our production lines also focus on environmental protection to reduce environmental pollution. We have adopted a series of environmental protection measures, including reducing exhaust gas and wastewater emissions and realizing the reuse of waste. These measures have played a very positive role in our production process, and are also important measures to fulfill our corporate social responsibility.

The 1100L plastic garbage bin production line provides us with very favorable production conditions, enabling us to create greater value for society. In the future, we will continue to improve production technology and equipment to provide consumers with higher quality products and better services. We believe that in the process of our continuous efforts, the 1100L plastic mobile garbage bin production line will be more and more refined, efficient and intelligent, and make greater contributions to our bright future.

How To Make A Good 1100L Large Mobile Garbage Bin Mould?

Making a 1100L large mobile garbage bin mould requires certain skills and experience, as well as attention to detail and quality. Here are some suggestions for making a 1100L large mobile garbage bin mould:

First, choose high-quality materials. The material of the mould is a key factor in its production and should be made of materials with high wear resistance, strength, and temperature tolerance. The material can ensure the durability and long-term lifespan of the mould.

Second, consider the design of the mould. Mould design is an important step in making moulds and it needs to take into account the dimensions, shape, structure, and functionality of the product. The design must also consider practical production processes to prevent mould failure issues. Thirdly, maintain accuracy. Accuracy is crucial during the process of making moulds. It is important to ensure that all manufacturing processes meet accuracy requirements in order to achieve the desired precision for final products. Fourthly, pay attention to safety. In producing moulds, it's necessary to pay attention on safety. Heavy machinery is required for producing large molds, and safety equipment and techniques should be used to ensure worker safety. In conclusion, making a 1100L large mobile garbage bin mould requires careful design, solid technical skills, and emphasis on details and quality. This way, a high-quality mold that meets requirements.

Video For 1100L Garbage Bin Mould

Design For Mould &. Product

Package &. Delivery

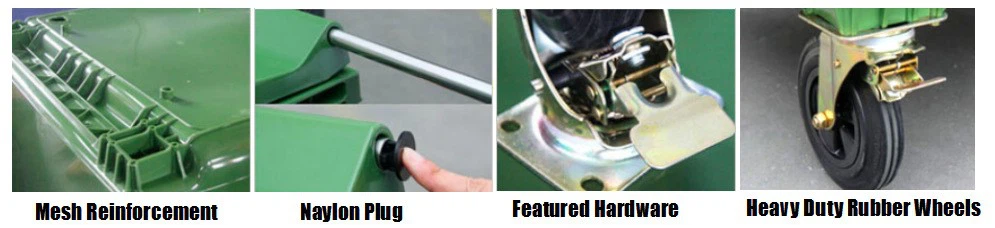

Mould Components

Mould Steel

Hot Runner System

Standard Parts

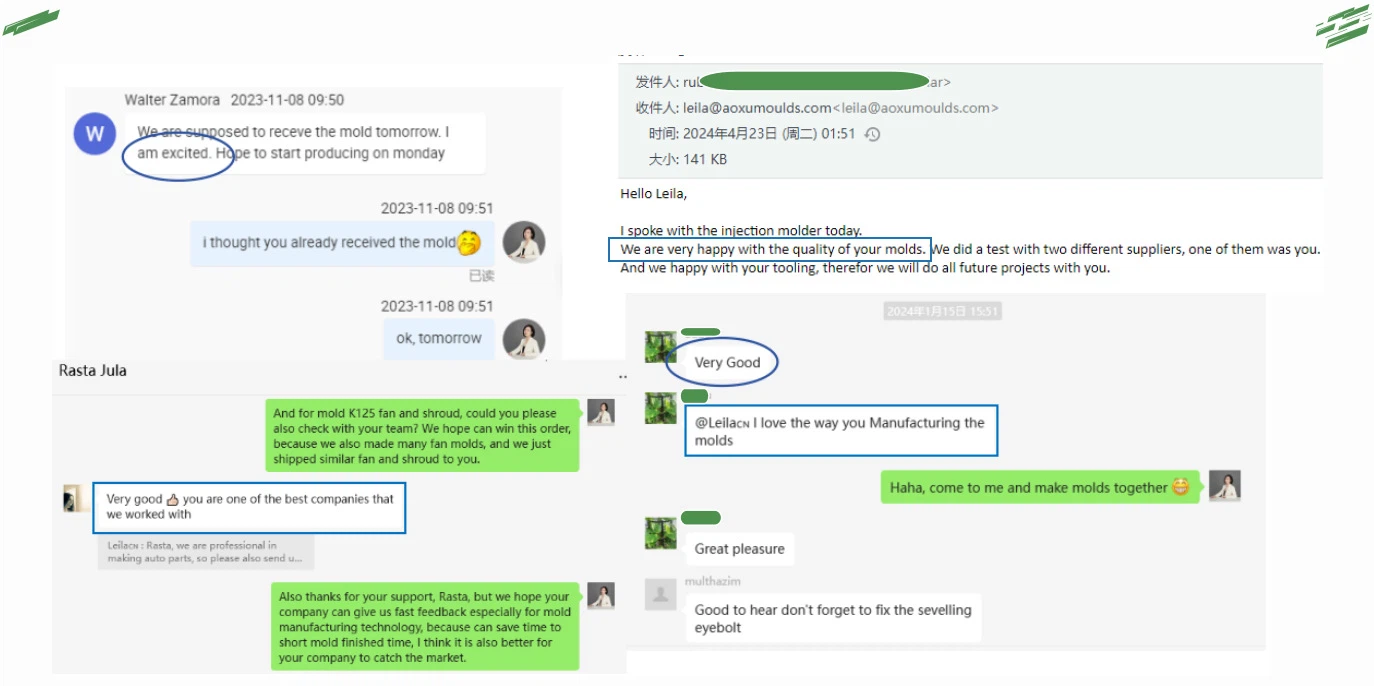

Customers' Feedback

FAQ